Metal Seals in Diesel Engine Applications: A Technical Guide

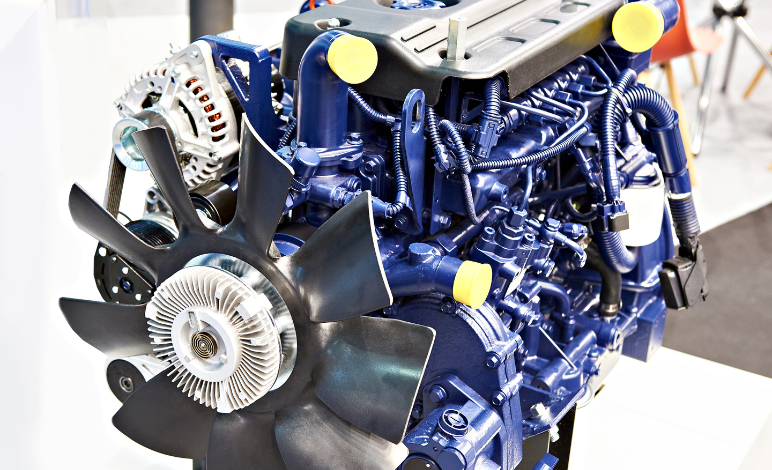

In the realm of diesel engine technology, metal ring seals represent a critical engineering achievement that fundamentally shapes engine performance, efficiency, and reliability. These sophisticated components serve as the cornerstone of engine integrity, managing extreme pressures, temperatures, and dynamic loads while ensuring optimal operational efficiency. Learn more about metal ring seal fundamentals and their applications.

Evolution and Significance in Modern Diesel Engines

The development of metal ring seals has paralleled the evolution of diesel engine technology. As engines have become more powerful and efficient, sealing requirements have grown increasingly demanding. Modern diesel engines, with their higher compression ratios and enhanced performance characteristics, rely heavily on advanced sealing solutions to maintain their operational integrity.

Types of Metal Seals in Diesel Applications

Different diesel engine applications require specific seal types, each engineered for optimal performance in their intended environment. Understanding these variations is crucial for proper seal selection:

Metal C-Ring Seals

Metal C-seals represent a sophisticated sealing solution particularly suited for critical diesel engine applications. For detailed specifications, visit our metal seal application guide:

- Design Characteristics:

- C-shaped cross-section providing controlled spring-back

- Available in both internal and external pressure configurations

- Optional plating for enhanced sealing (Silver, Gold, or PTFE)

- Performance Specifications:

- Pressure ratings: Vacuum to 350 bar

- Temperature range: -250°C to 950°C

- Typical compression: 15-30% of seal height

- Primary Applications:

- Cylinder head gasket sealing

- Turbocharger housing joints

- Exhaust system connections

Metal O-Ring Seals

Metal O-rings provide robust sealing solutions for high-pressure applications:

- Design Features:

- Solid or hollow construction options

- Precision-machined surface finish

- Available with energizing springs for enhanced recovery

- Performance Characteristics:

- Pressure capability: Up to 400 bar

- Temperature resistance: -200°C to 870°C

- Leakage rate: 10⁻⁹ mbar·l/s

Spring-Energized Metal Seals

These advanced seals combine the durability of metal with enhanced recovery properties:

| Design Type | Spring Configuration | Typical Applications |

|---|---|---|

| U-Spring Design | Cantilever spring element | High-temperature exhaust systems |

| V-Spring Design | V-shaped spring insert | Cylinder head assemblies |

| Helical Spring Design | Continuous helical spring | Turbocharger housings |

Metal E-Ring Seals

Metal E-seals offer unique advantages for specific diesel engine applications:

- Key Features:

- W-shaped cross-section providing dual sealing surfaces

- Enhanced stability under thermal cycling

- Superior resistance to torsional movement

- Application Areas:

- High-vibration environments

- Thermal cycling applications

- Limited-space installations

Fundamental Operating Principles and Critical Functions

| Operational Aspect | Technical Requirements | Performance Impact |

|---|---|---|

| Combustion Chamber Sealing | Dynamic pressure resistance up to 200 bar with peak transients to 220 bar | Directly influences power output and fuel efficiency |

| Thermal Management | Stable performance from cold start (-40°C) to full load (300°C+) | Critical for emissions control and engine longevity |

| Dynamic Response | Microsecond adaptation to pressure fluctuations | Ensures consistent compression ratios and power delivery |

Advanced Material Science in Seal Design

The selection of materials for metal ring seals represents a careful balance between competing requirements. Modern seal designs incorporate sophisticated metallurgy and surface engineering to achieve optimal performance:

Primary Material Categories

- Advanced Stainless Steel Alloys:

- Martensitic grades (e.g., 440C):

- Hardness: 58-62 HRC

- Tensile Strength: 1900-2000 MPa

- Application: High-pressure sealing zones

- Austenitic grades (316L):

- Superior corrosion resistance

- Enhanced low-temperature ductility

- Optimal for cryogenic applications

- Martensitic grades (e.g., 440C):

- Nickel-Based Superalloys:

- Inconel X-750:

- Temperature capability: Up to 760°C

- Exceptional spring characteristics

- Superior resistance to thermal fatigue

- Inconel X-750:

Surface Engineering and Coating Technologies

Modern metal ring seals employ sophisticated surface treatments to enhance their performance characteristics:

| Coating Type | Application Method | Performance Benefits |

|---|---|---|

| Diamond-Like Carbon (DLC) | Physical Vapor Deposition | Ultra-low friction coefficient (0.1-0.2) |

| Chromium Nitride | Plasma-Enhanced CVD | Enhanced wear resistance, 2000-2500 HV hardness |

| PTFE Composite | Spray Application + Sintering | Self-lubricating properties, chemical inertness |

Performance Validation and Quality Assurance

The validation of metal ring seals involves comprehensive testing protocols that simulate real-world operating conditions while pushing the boundaries of performance requirements:

Advanced Testing Methodologies

- Dynamic Performance Testing:

- High-frequency pressure cycling:

- Frequency range: 0-200 Hz

- Pressure amplitude: 0-200 bar

- Duration: 10⁷ cycles minimum

- Thermal shock resistance:

- Temperature ramp rate: 100°C/minute

- Cycle count: 1000 minimum

- Hold time: 30 minutes at temperature extremes

- High-frequency pressure cycling:

Contact

For technical support and custom solutions:

- Technical Support: support@sonkit.cn

- Sales Inquiries: sales@sonkit.cn

- Emergency Support: +86 13917192435

- Technical Documentation: Download Center

Expert Diesel Engine Sealing Solutions & Technical Support

Access Sonkit's comprehensive technical expertise for customized metal sealing solutions designed specifically for your diesel engine applications. Our engineering team provides:

- Custom design consultation

- Material selection guidance

- Installation support

- Performance optimization

Industry Developments and Future Trends

The metal sealing industry continues to evolve with new technologies and applications. Recent developments include:

- Advanced manufacturing techniques showcased at Fakuma 2024

- Innovative testing methods presented at HTE 2024

- Latest turbocharger sealing solutions featured in our 2024 company update

Additional Resources

For more information about metal sealing technologies and standards, consult these authoritative sources:

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch

Service

Hotline

Service

Hotline