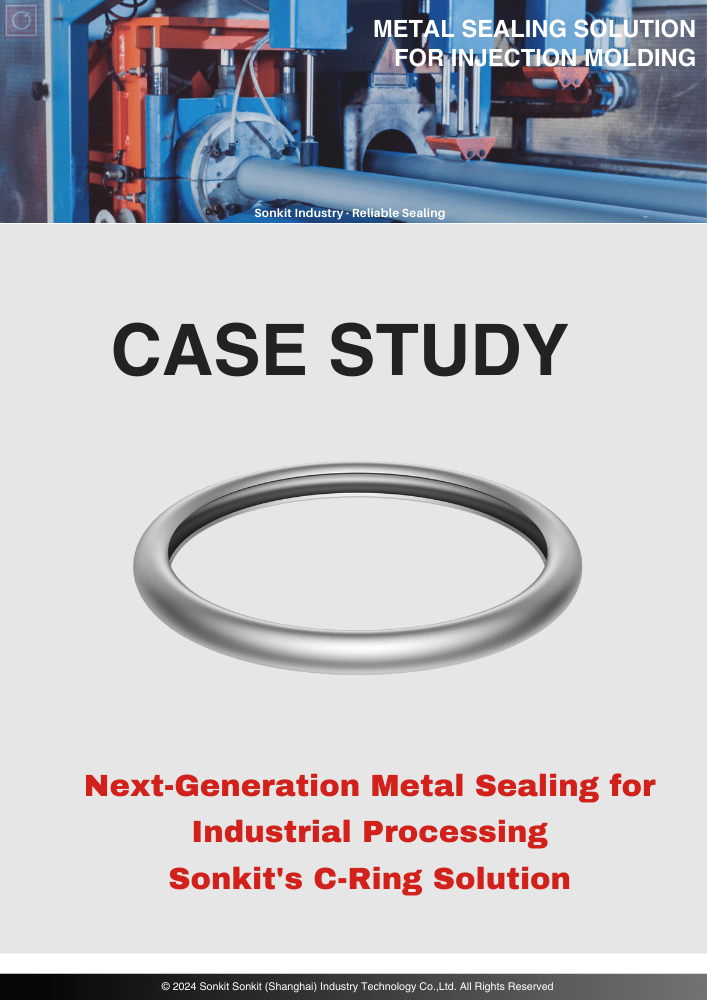

In the demanding world of injection molding, maintaining long-term

sealing stability in high-temperature and high-pressure environments is essential for reliable equipment

operation. Hot runner mold systems present significant challenges, including extreme temperature conditions,

high-pressure resistance, compatibility with molten plastics and synthetic fibers, and the need for high

reliability.

Sonkit Industry Technology Co., Ltd. has developed a high-performance

metal C-ring seal specifically designed to meet these challenges. This innovative, internally open,

spring-energized metal C-ring, made from thin-walled materials, achieves precision machining tolerances of

±0.05mm, allowing for full compression within limited installation spaces and forming a highly reliable

seal.

Key specifications of Sonkit's metal C-ring seals for injection

molding:

- Seal Type - Internally open, spring-energized metal C-ring

- Material - Thin-walled metal

- Temperature Resistance - -50°C to 400°C

- Pressure Tolerance - Vacuum to 40 MPa

- Medium - Molten plastics and synthetic fibers

The Sonkit C-ring seal offers several key advantages:

- Superior Performance in Extreme Conditions:

The seal maintains its integrity across a wide temperature

range and under high pressure, ensuring reliable operation in demanding injection molding

environments.

- Compatibility with Molten Media:

The seal is designed to effectively seal molten plastics and

synthetic fibers, preventing leakage and maintaining consistent melt flow.

The robust design and precision manufacturing contribute to

long-term operational stability, reducing maintenance and replacement frequency in hot runner molds and

chemical fiber spinnerets.

Achieving ±0.05mm tolerances ensures the seal can be

fully compressed within the limited installation space typical of injection molding equipment.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch