Ultra-high vacuum (UHV) applications in semiconductor manufacturing

and scientific research present significant sealing challenges. These applications demand solutions capable of

withstanding extreme conditions, including wide temperature ranges, variable pressures, and corrosive gases,

while also adhering to strict purity and ultra-low leakage requirements.

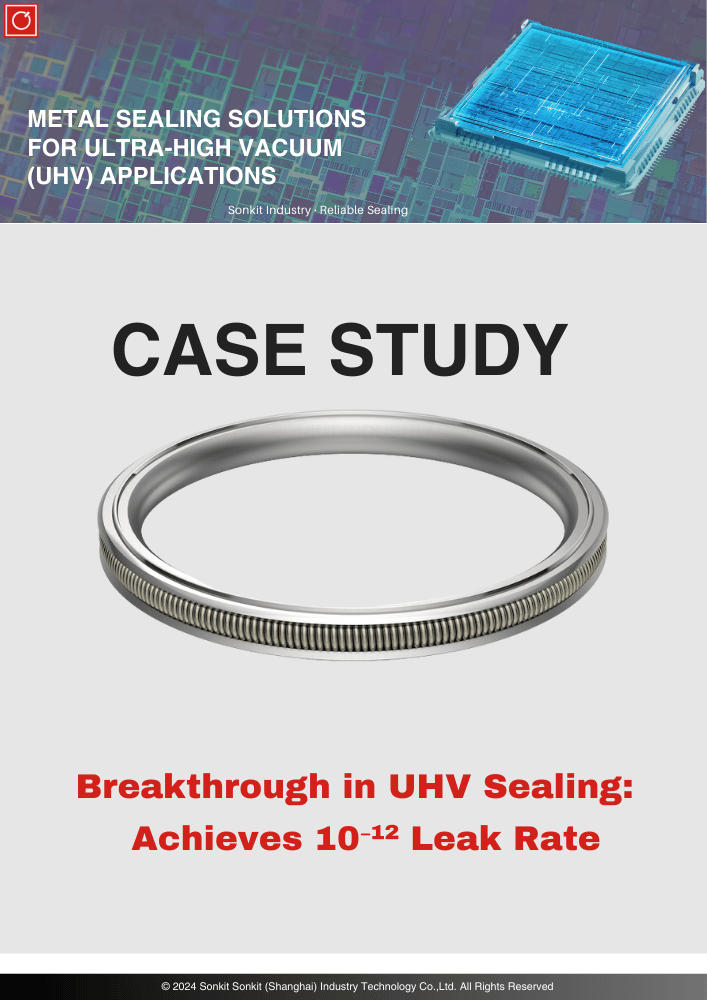

Sonkit Industry Technology Co., Ltd. has developed a knife-edge,

spring-energized metal C-ring specifically designed for these demanding UHV environments. This innovative seal

replaces conventional stainless steel spring-energized metal C-rings, enabling effective compression and

deformation with minimal bolt-tightening force. The unique knife-edge structure creates a true line seal,

providing exceptional reliability in vacuum applications.

Key specifications of Sonkit's metal C-ring seals for UHV

applications:

- Seal Type - Knife-edge, spring-energized metal C-ring

- Temperature Resistance - -270°C to 300°C

- Pressure Tolerance - Ultra-high vacuum (UHV) to 1 bar

- Medium - Corrosive gases, including fluorine, ammonia, and

argon.

The Sonkit C-ring seal offers several key advantages:

- Lower Bolt Tightening Force:

This seal requires less bolt tightening force than

traditional metal seals, making it a suitable replacement for rubber and non-metallic seals.

- Outstanding Performance in Extreme Environments:

It excels in high temperatures, high pressures, corrosive

conditions, and ultra-low leakage applications.

- Enhanced Safety and Long-Term Stability:

The design ensures enhanced safety and long-term stability

for scientific research, semiconductor, and high-tech vacuum applications.

The seal achieves a leakage rate of 1 ×

10-12 Pa·m3/s, exceeding industry benchmarks for UHV applications.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch