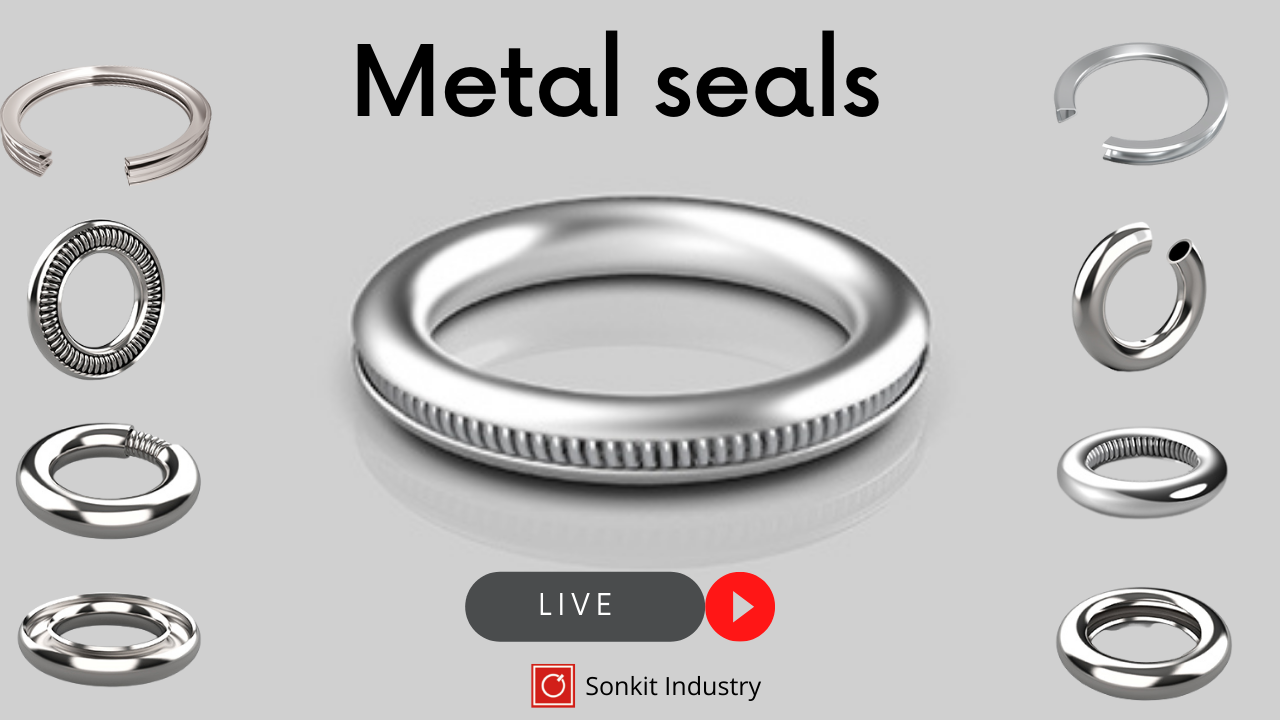

Advantages of Metal Seal Rings: Superior Solutions for Extreme Environments

In the most challenging industrial environments, metal seal rings stand out as the premier sealing solution. These resilient metal seals excel in conditions that would compromise conventional sealing materials, including:

- Extreme high temperatures and cryogenic environments

- High pressure and high vacuum applications

- Exposure to corrosive chemicals

- Intense radiation environments

Metal seals are engineered to perform dependably for many years under these demanding conditions, offering unparalleled reliability and longevity.

Key Advantages of Metal Seal Rings

1. Independent Optimization of Functional Components

Metal seal rings allow for discrete optimization of critical functions, including:

- Load-bearing capacity

- Spring-back performance

- Outer sealing layer ductility and hardness

This independent optimization ensures the highest seal performance across diverse applications and conditions.

2. Superior Electroplating Techniques

Direct bonding of electroplating onto the load-bearing substrate eliminates unnecessary parts and potential failure modes, enhancing overall reliability and performance.

3. Pressure Energization

Metal seals utilize internal hydrostatic pressures to supplement self-energization forces from the tubing, jacket, or spring. This feature is particularly beneficial in high-pressure applications:

- Effective at pressures exceeding 3,000 psi (21 MPa)

- Enables sealing at extreme pressures up to 25,000 psi (170 MPa) and beyond

- Mitigates the risk of blow-by during proof or burst testing

4. Versatility Across Industries

Metal seal rings are the preferred solution in a wide range of high-performance applications, including:

- Aerospace: Jet engine and space applications

- Oil and Gas: Exploration and processing equipment

- Chemical Processing: Reactors and transport systems

- Manufacturing: Plastic molding and high-precision tooling

- Automotive: Diesel engines and advanced powertrain systems

- Industrial Equipment: Various critical sealing applications

Meeting Future Challenges

As industries face increasingly stringent pollution control and leakage prevention regulations, coupled with demands for greater efficiency and lifetime reliability, metal seal rings provide the highest reliability sealing solutions. These advanced seals are not only meeting today's challenging requirements but are also poised to address the evolving needs of tomorrow's industrial landscape.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch

Service

Hotline

Service

Hotline