Groove Finish Requirements for Optimal Metal Seal Performance

The groove finish of mating hardware is a critical factor in achieving effective metal sealing. At Sonkit, we understand the importance of proper surface preparation for optimal seal performance. This guide outlines our recommendations for minimum groove finish requirements across various media types.

Recommended Groove Finish for Different Media

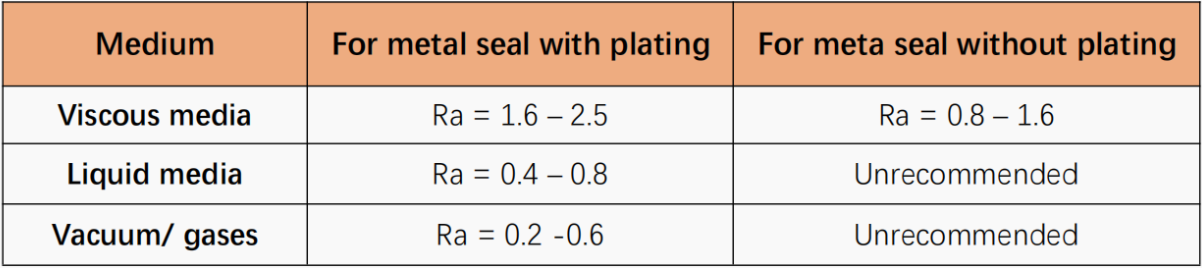

Unlike elastomers, metals do not compress easily, making a smooth or well-matched groove surface crucial for effective metal sealing. Based on extensive testing and real-world applications, Sonkit recommends the following roughness rates (Ra) for different media:

| Media Type | Recommended Ra (μm) |

|---|---|

| Viscous Media | 1.6 - 2.5 |

| Liquid Media | 0.4 - 0.8 |

| Vacuum Media | 0.2 - 0.6 |

Customization for Specific Applications

While these parameters serve as our standard recommendations, Sonkit can produce metal seals that match groove finishes beyond these ranges, depending on the specific sealing performance requirements of your application. For instance, surfaces exceeding 3 Ra may not achieve a bubble-tight seal (leakage rate of 1x10^-4 cc/sec) but could be sufficient for certain applications.

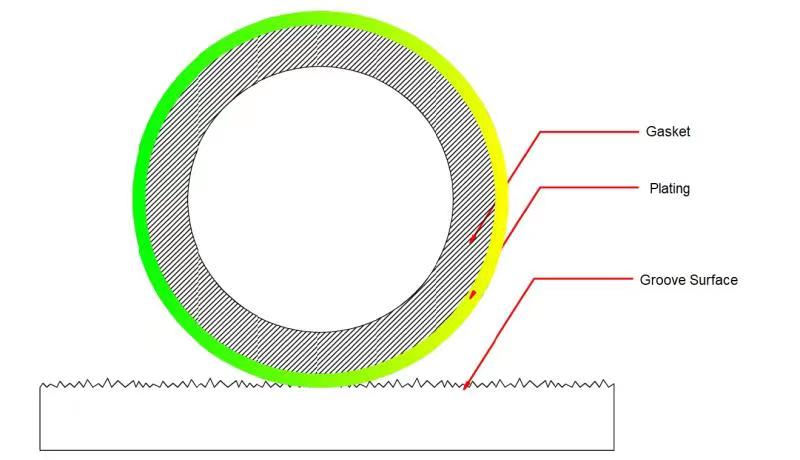

Enhancing Sealing Performance with Coatings

In some applications, higher surface roughness can be mitigated through the use of specialized coatings applied to the metal seal. These coatings can effectively navigate the peaks and valleys of the hardware surface, achieving the desired sealing effect even on rougher surfaces.

Conclusion

The groove finish roughness plays a significant role in the sealing effectiveness of metal rings. Understanding and adhering to proper surface preparation standards is crucial for optimal seal performance. Sonkit is committed to providing not only high-quality metal seals but also the expertise needed to ensure their proper installation and function.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch

Service

Hotline

Service

Hotline