Metal Sealing Methods for Ultra-High Vacuum Applications: A Comprehensive Technical Analysis

In ultra-high vacuum (UHV) systems, the integrity of sealing solutions plays a pivotal role in maintaining system performance and reliability. While conventional sealing materials such as rubber, polytetrafluoroethylene (PTFE), and polyurethane have their applications, metal sealing solutions have emerged as the superior choice for ultra-high vacuum environments, particularly where high temperature and radiation resistance are required.

Fundamental Requirements for UHV Sealing

Ultra-high vacuum applications demand exceptional sealing performance, with leak rates typically required to be below 1 × 10⁻¹¹ Pa·m³/s. This stringent requirement necessitates precise control of flange sealing surface roughness, maintained at Ra ≤ 0.8. Metal sealing rings, combining excellent elasticity and ductility, have proven ideal for meeting these demanding specifications.

Metal Seal Material Selection

The primary materials employed in UHV metal seals include oxygen-free copper, pure aluminum, gold, and silver. These relatively soft metals are selected for their specific mechanical properties. Oxygen-free copper and pure aluminum have become standard choices for general applications due to their cost-effectiveness, with copper seals being particularly prevalent in Conflat (CF) flanges, as standardized in GB/T 6071-2003 "Ultra-High Vacuum Flanges."

Advanced Metal Sealing Methods

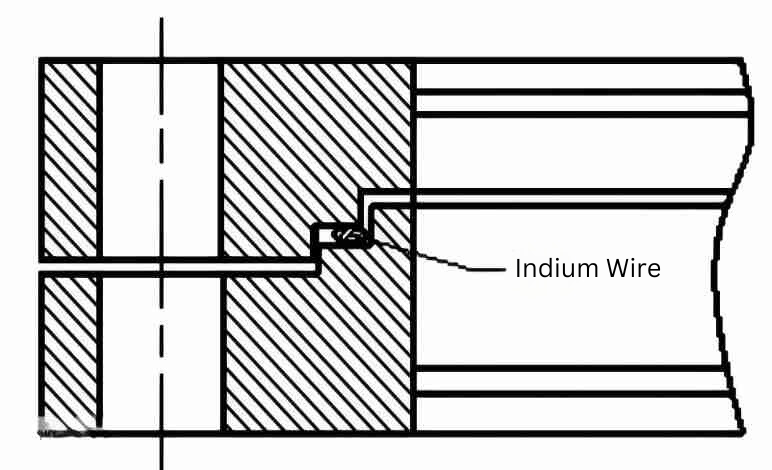

Indium Wire Sealing Technology

Indium wire sealing represents a unique solution in UHV applications, distinguished by its remarkably low Mohs hardness of 1.2 (compared to copper at 2.5-3 and aluminum at 2-2.9) and melting point of 156.6°C. The exceptional ductility of indium enables effective sealing without requiring pre-fabricated rings, making it particularly valuable for large flanges or complex geometries.

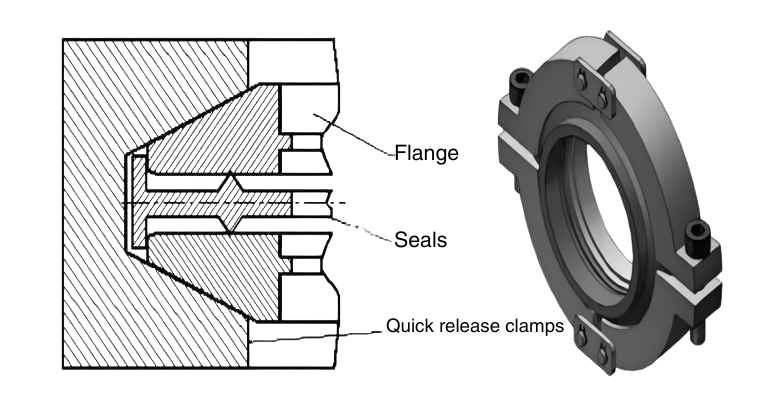

All-Metal Quick-Release Sealing Systems

Quick-release metal sealing systems offer significant advantages in installation efficiency, requiring only two screws compared to traditional multi-bolt configurations. This system comprises quick-release clamps, flat flanges, and sealing rings, optimized for applications where rapid assembly and disassembly are crucial.

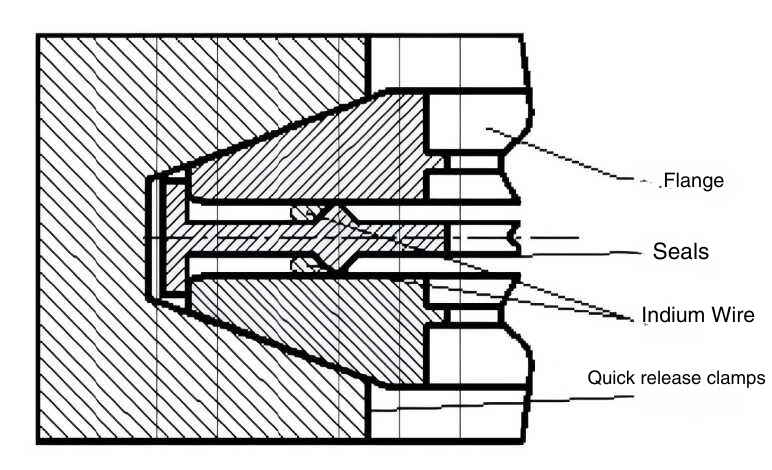

Hybrid Sealing Solutions

The combination of quick-release metal seals with indium wire technology represents an innovative approach to addressing sealing challenges in confined spaces. This hybrid solution extends gas leakage pathways while positioning the indium wire outside the primary seal, effectively preventing potential melting issues in high-temperature applications.

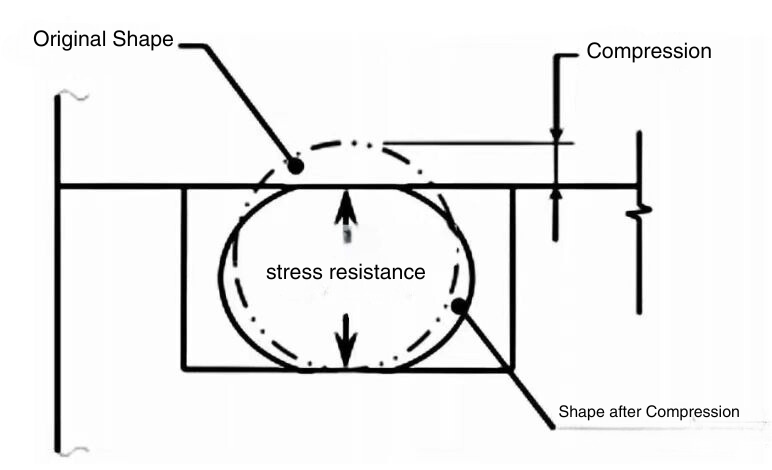

Helicoflex Sealing Technology

The dual-layer knife-edge spring-energized metal C-ring seal (Helicoflex) represents advanced sealing technology, combining metallic jackets made from aluminum, copper, silver, or stainless steel with energizing springs. This design provides consistent sealing force through spring compression while accommodating thermal expansion and mechanical misalignment.

Applications and Performance Considerations

The selection and implementation of metal sealing solutions in UHV systems requires careful consideration of operational parameters. For indium wire sealing applications, the temperature limitation of 150°C must be strictly observed due to indium's relatively low melting point. This characteristic makes indium wire seals particularly suitable for low-temperature applications, where they demonstrate exceptional sealing performance.

Quick-Release Sealing System Design

The effectiveness of all-metal quick-release sealing systems is closely tied to flange diameter considerations. As the nominal diameter increases, the axial clamping force provided by the quick-release clamp decreases proportionally under constant screw fastening force. Empirical testing has demonstrated optimal sealing performance for flanges with nominal diameters below φ160. This limitation must be carefully considered during system design.

Space-Constrained Applications

In applications where axial space is limited, the elimination of traditional axial screws through quick-release designs offers significant advantages. This design consideration becomes particularly crucial in high-energy accelerator environments, where rapid installation and removal may be necessary due to residual radiation concerns. The Institute of High Energy Physics of the Chinese Academy of Sciences has established comprehensive internal testing standards for these applications, validating their effectiveness across multiple accelerator installations.

Advanced Hybrid Sealing Solutions

The development of combination sealing methods, particularly the integration of indium wire with quick-release metal seals, represents a significant advancement in addressing complex sealing challenges. This hybrid approach effectively extends gas leakage pathways, substantially reducing leakage conductance while maintaining system integrity. The strategic positioning of indium wire outside the primary metal seal mitigates concerns regarding high-temperature exposure, enhancing overall system reliability.

Helicoflex Technology Implementation

The dual-layer knife edge open spring reinforced metal C-type seal (Helicoflex) exemplifies advanced sealing technology. This sophisticated design incorporates pressure-assisted sealing mechanisms through the combination of metallic materials with energy-storing springs. When installed in sealing grooves, the compression of internal springs forces the seal jacket to maintain consistent contact with groove walls, ensuring reliable sealing performance.

The spring's elastic properties provide crucial compensation for material wear and potential misalignments between mating components. Furthermore, the design leverages internal system pressure to provide auxiliary support to the sealing jacket, establishing a continuous and stable pre-tightening force through the combined action of spring force and system pressure.

Industry Applications and Standards

Metal sealing solutions find critical applications across various demanding industries. In ultra-high vacuum systems, nuclear facilities, aerospace applications, and chemical processing installations, these seals must meet stringent performance requirements. The standardization of certain seal types, such as copper seals in CF flanges (GB/T 6071-2003), ensures consistency and reliability across different applications.

Future Developments and Trends

The evolution of metal sealing technology continues to advance, driven by increasingly demanding applications in scientific research and industrial processes. Current development trends focus on enhancing seal performance through improved material science, innovative design geometries, and advanced manufacturing techniques. The integration of smart monitoring capabilities and predictive maintenance features represents an emerging frontier in metal seal technology.

Enhance Your Vacuum System Performance with Sonkit's Metal Sealing Solutions

Looking for reliable metal sealing solutions for your ultra-high vacuum applications? Sonkit specializes in high-performance metal seals designed for the most demanding vacuum environments.

- Custom-engineered solutions for specific vacuum requirements

- Advanced materials and precision manufacturing

- Comprehensive technical support

- Proven reliability in ultra-high vacuum applications

Contact us today to discover how our metal sealing solutions can optimize your vacuum system performance.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch

Service

Hotline

Service

Hotline