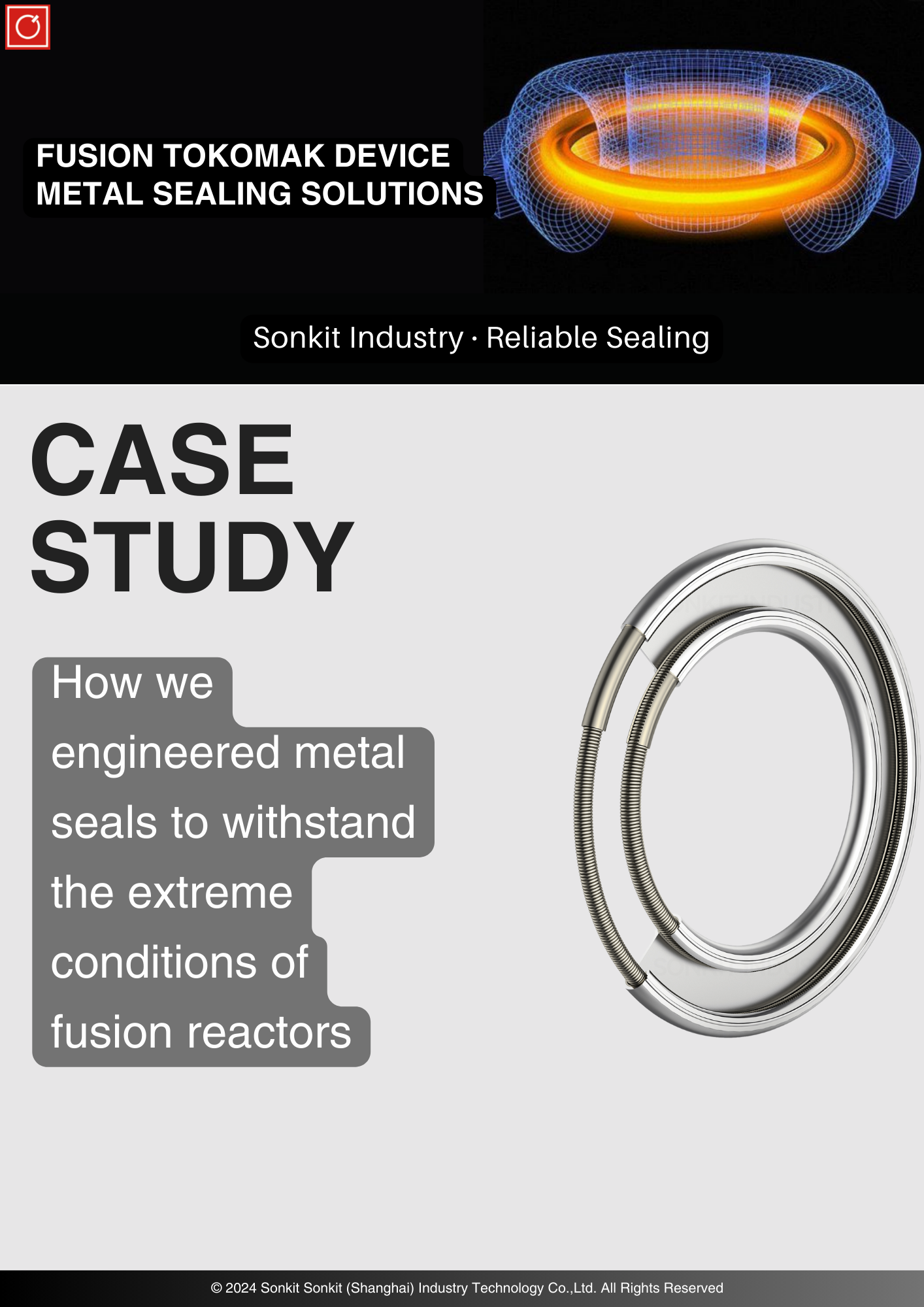

CIPP-type Two-stage Metal Sealing Solution for Tokamak Devices

Next-Generation Sealing for Nuclear Fusion

Sonkit introduces the CIPP-type two-stage metal sealing solution, developed in collaboration with the Institute of Plasma Physics, Chinese Academy of Sciences. This innovative seal addresses critical challenges in nuclear fusion tokamak devices, including extreme temperatures ranging from -270°C to 350°C, ultra-high vacuum environments, and exposure to high-energy particle beam radiation.

Dual-Stage, Multi-Layer Composite Structure

Designed with a dual-stage, multi-layer composite structure, the CIPP-type seal ensures exceptional performance in extreme conditions, far surpassing the original leakage rate requirements. The seal's proprietary knife-edge design compensates for flange flatness, making it easier to install and ensuring a secure, reliable fit.

Superior Sealing Performance

The CIPP-type dual-stage metal seal's robust sealing capability ensures long-term performance under the unique demands of nuclear fusion applications. The dual-layer construction enhances durability and guarantees effective sealing in high-pressure conditions (up to 10 MPa) while maintaining a low leakage rate of 1E-11 mbar l/s. This performance exceeds expectations and provides a solution for achieving high vacuum integrity necessary for nuclear fusion systems.

Advancing Nuclear Fusion Technology

By providing a seal that can withstand the harsh operating conditions found in tokamak devices, Sonkit's solution helps advance the development of nuclear fusion technology. With the ability to operate in extreme temperatures, high radiation, and ultra-high vacuum, while offering lower installation difficulty, this innovative metal seal contributes to the success of fusion reactors, supporting the pursuit of clean and sustainable energy.

Press Download to view the full article.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch