Sonkit Enhances Metal Sealing Solutions with AMS2750-Compliant Heat Treatment Furnace

Date: October 26, 2024

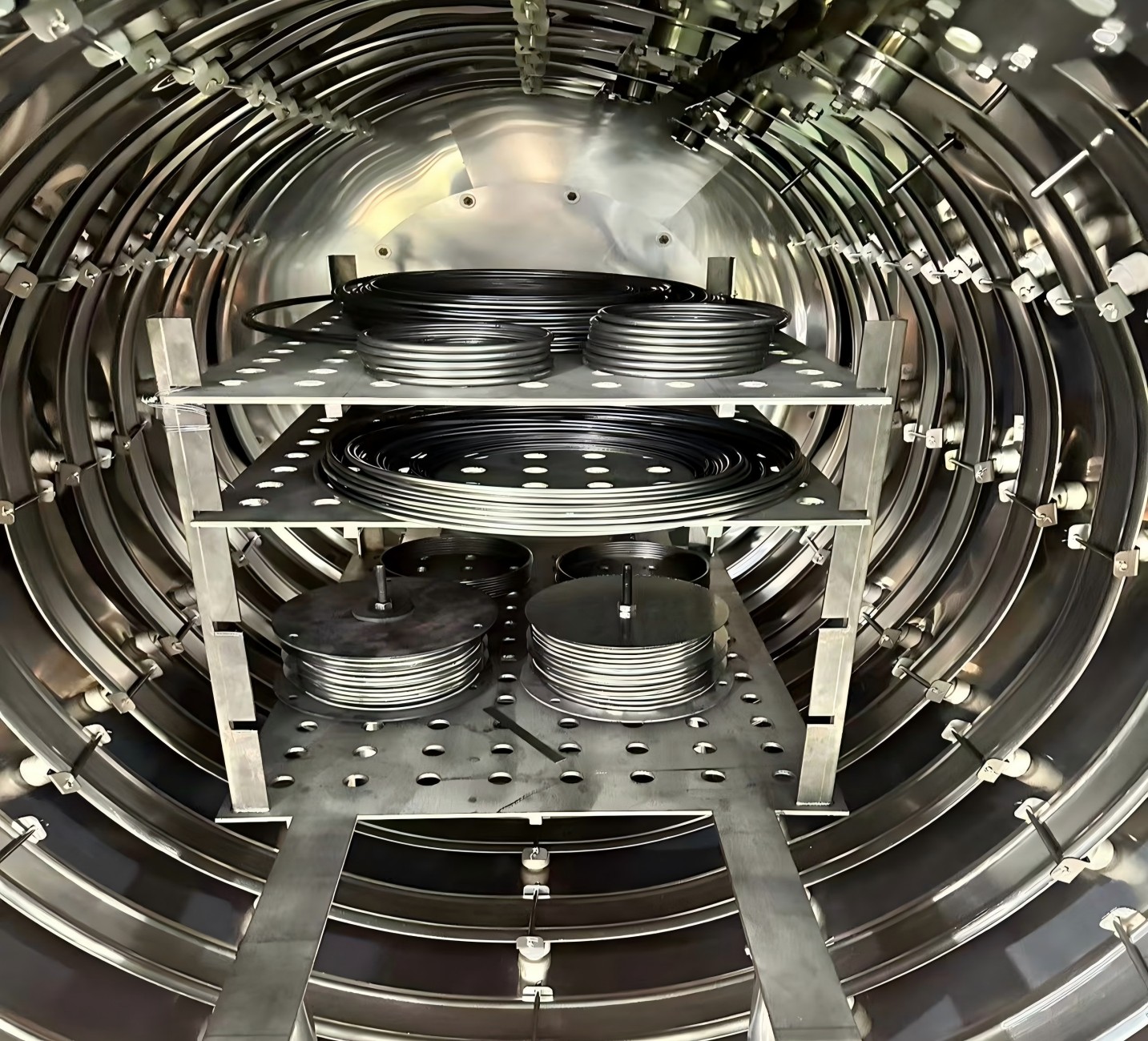

Sonkit (Shanghai) Industrial Technology Co., Ltd., a leading metal seal manufacturer, proudly announces that its newly equipped heat treatment furnace has been officially put into operation, successfully complying with the AMS2750 standard. This significant achievement marks a new milestone in Sonkit's commitment to providing top-tier metal sealing solutions for industries demanding the highest quality standards.

Setting New Standards in Heat Treatment

The AMS2750 standard, established by the Society of Automotive Engineers (SAE International), represents the pinnacle of temperature control and management in heat treatment processes. This certification is particularly crucial for the aerospace industry, where precision and reliability are non-negotiable requirements. As a trusted metal seal manufacturer, Sonkit's achievement reinforces its position in providing high-performance metal seals for critical applications.

Advancing Aerospace Manufacturing Excellence

In the aerospace sector, heat treatment plays a vital role in enhancing the mechanical properties and corrosion resistance of materials. The process significantly improves the reliability and longevity of critical components, particularly for resilient metal seals and metal seal rings used in demanding aerospace applications. Sonkit's new AMS2750-compliant furnace ensures precise temperature control throughout the heat treatment process, preventing issues such as decreased material performance, component deformation, or potential system failures that could arise from even minor temperature variations.

Investing in Cutting-Edge Technology

Responding to evolving market demands, Sonkit has made substantial investments in state-of-the-art technology. The newly installed heat treatment furnace enhances our capability to produce superior metal sealing solutions, featuring advanced temperature sensors and intelligent control systems. This technological advancement enables comprehensive monitoring and detailed recording throughout the entire heat treatment process, ensuring the highest quality standards for our metal sealing rings.

Ensuring Superior Quality Through Rigorous Validation

Sonkit's technical team has implemented comprehensive calibration and validation procedures to ensure that all equipment meets or exceeds industry standards before deployment. This meticulous approach guarantees the production of superior metal seals, including specialized metal seal rings and custom metal sealing solutions, providing customers with increasingly reliable sealing solutions for their most demanding applications.

Expanding Product Excellence

The new heat treatment facility significantly enhances Sonkit's capabilities as a premier metal seal manufacturer. Our expanded range of high-quality products includes advanced resilient metal seals, precision-engineered metal sealing rings, and customized metal sealing solutions. Each product undergoes rigorous quality control measures, ensuring optimal performance in critical applications across various industries.

Looking Ahead: A Commitment to Innovation

Looking forward, Sonkit remains dedicated to its founding principle of "Quality First, Customer Foremost." As a leading metal seal manufacturer, we continue to advance our technical expertise and enhance service quality, striving to make greater contributions to the aerospace industry and other sectors where high-performance metal sealing solutions are essential. This investment in AMS2750-compliant technology represents another step forward in Sonkit's journey of continuous improvement and innovation in metal seal manufacturing.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch

Service

Hotline

Service

Hotline