Advanced Spring Energized C-Ring Metal Sealing Solution for Ultra-High Vacuum Applications

Revolutionizing Sealing for Ultra-High Vacuum Environments

In this case study, we highlight Sonkit's innovative metal sealing solution for ultra-high vacuum (UHV) applications, designed to meet the demanding requirements of scientific research and semiconductor operations. Our UHV sealing solution achieved an impressive leakage rate of 10-12 Pa·m3/s, exceeding industry benchmarks for ultra-low leakage.

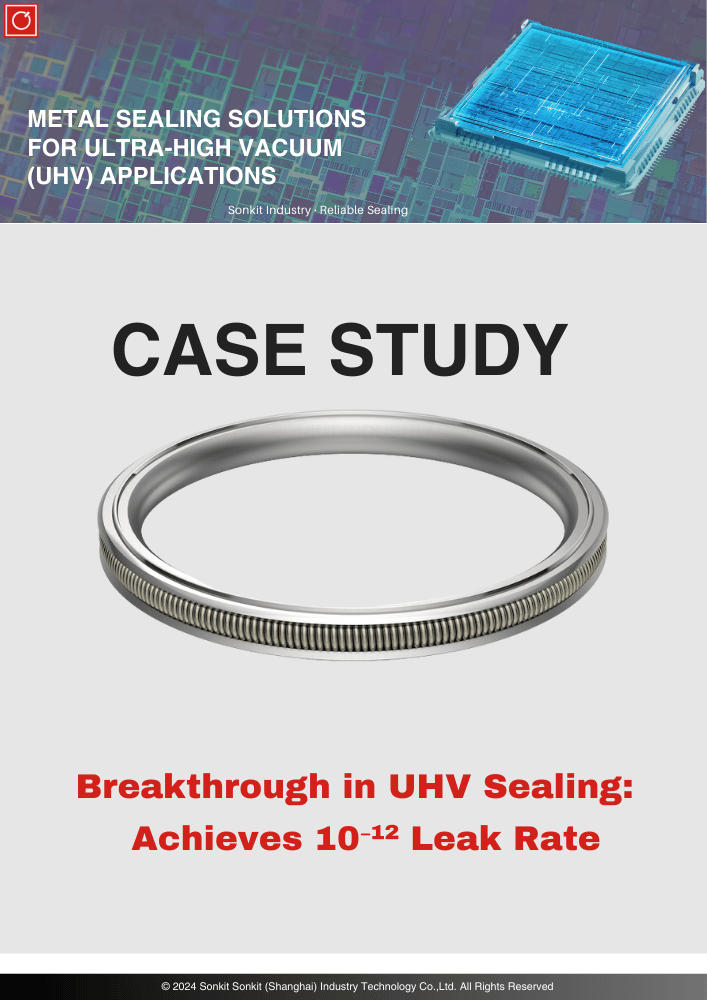

Knife-Edge, Spring-Energized Metal C-Ring

Sonkit developed a knife-edge, spring-energized metal C-ring that outperforms traditional seals, offering effective compression and deformation under minimal bolt tightening force. This unique design provides true line sealing, ensuring reliable performance in UHV conditions. The seal operates effectively across a broad temperature range from -270°C to 300°C and withstands fluctuating pressures from ultra-high vacuum to atmospheric levels.

Superior Longevity & Corrosion Resistance

The spring-energized design compensates for material wear and temperature changes, enhancing seal longevity. Additionally, the seal is highly resistant to corrosive gases like fluorine, ammonia, and argon, ensuring cleanroom compatibility for use in high-tech environments such as light sources, vacuum chambers, and semiconductor manufacturing.

Delivering Long-Term Performance

Sonkit’s UHV seal solution offers exceptional reliability and long-term stability in extreme environments, delivering high performance with minimal maintenance. This makes it an ideal choice for applications requiring ultra-low leakage, high purity, and high-temperature resistance in scientific and semiconductor industries.

Press Download to view the full article.

Language

Language

China

China German

German French

French Italian

Italian Spanish

Spanish Turkish

Turkish Arabic

Arabic Dutch

Dutch